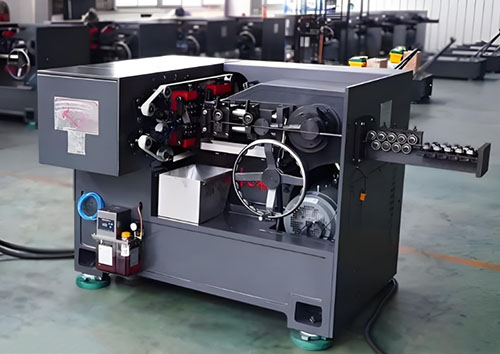

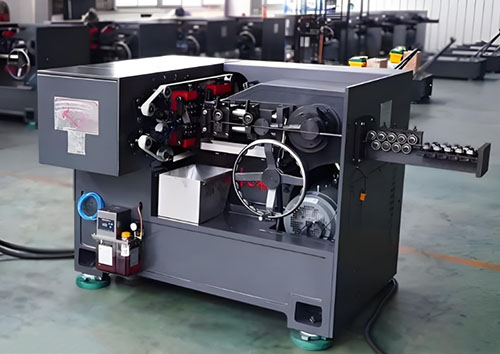

High-Speed Nail Making Machine

May 29, 2025

A high-speed nail making machine is advanced industrial equipment designed for the efficient and automated production of various nails, including common nails, roofing nails, concrete nails, stainless steel nails, and more. It integrates mechanical engineering, precision control, and material processing technologies to meet the high-volume manufacturing demands of the construction, furniture, packaging, and hardware industries.Key Features and Advantages

-

High Efficiency & Productivity

- Capable of producing nails at extremely high speeds (e.g., 800–2,000 nails per minute), significantly reducing production time and labor costs.

- Fully automated operation from wire feeding, cutting, heading, and point forming to quality inspection and packaging.

-

Precision and Consistency

- Uses advanced CNC (Computer Numerical Control) systems and high-precision molds to ensure uniform nail dimensions (length, diameter, head shape) and superior surface finish.

- Minimizes defects such as bent nails, incomplete heads, or uneven points.

-

Material Versatility

- Processes various wire materials, including carbon steel, stainless steel, aluminum, and copper, with wire diameters ranging from 0.8 mm to 6 mm (customizable based on models).

- Adaptable to different surface treatments (e.g., galvanized, black oxide) for corrosion resistance.

-

User-Friendly Operation

- Human-machine interface (HMI) for easy parameter setting (nail length, head size, production speed) and real-time monitoring of machine status.

- Quick-change mold systems enable fast switching between different nail types, reducing downtime during product transitions.

-

Safety and Reliability

- Equipped with emergency stop mechanisms, protective covers, and automatic fault detection systems to ensure operator safety and stable performance.

- Built with durable alloy steel components and high-quality bearings for long service life and low maintenance requirements.

-

Energy Efficiency

- Low-power consumption motors and optimized mechanical designs reduce energy waste, aligning with environmental sustainability goals.

- Wire Feeding: The raw wire is unwound from a coil and fed into the machine via a straightening mechanism to eliminate curvature.

- Cutting: The wire is cut into precise lengths by a high-speed cutting blade.

- Heading: The cut wire segment is transferred to the heading station, where a punch and die form the nail head through high-frequency impact.

- Point Forming: The tip of the nail is shaped using a specialized die, ensuring sharpness and penetration efficiency.

- Quality Inspection: Automated sensors check for defects (e.g., misshapen heads, incorrect length) and reject non-conforming nails.

- Collection & Packaging: Finished nails are sorted, counted, and packaged into bags or boxes for distribution.

- Construction Industry: Producing nails for framing, roofing, and concrete applications.

- Furniture Manufacturing: Manufacturing small nails for joinery and upholstery.

- Packaging Sector: Creating nails for wooden crates and pallets.

- Hardware and DIY Markets: Supply of nails for general repair and crafting purposes.

- Automotive and Aerospace: Specialized nails for lightweight or high-strength applications (e.g., aluminum nails).

| Parameter |

Standard Model |

High-End Model |

| Production Speed |

1,000–1,500 nails/min |

1,800–2,200 nails/min |

| Wire Diameter |

1.2–4.0 mm |

0.8–6.0 mm |

| Nail Length |

15–100 mm |

10–150 mm |

| Power Supply |

380V/50Hz 3-phase |

380V/50Hz 3-phase |

| Machine Dimensions |

4.5m × 1.8m × 1.9m |

5.2m × 2.0m × 2.2m |

| Weight |

3,500 kg |

5,000 kg |

- Professional installation and training by technical teams.

- Regular maintenance services and genuine spare parts supply.

- 24/7 remote troubleshooting and lifelong technical consultation.

Conclusion: High-speed nail making machines are essential for modern manufacturing, offering unmatched speed, precision, and flexibility. They empower businesses to scale production, maintain high-quality standards, and stay competitive in global markets. Whether for small workshops or large industrial facilities, these machines are a cornerstone of efficient nail production.

IPv6 RED SOPORTADA

IPv6 RED SOPORTADA